Ultimate Guide to Preventing Weld Undercut: Tips and Techniques

Ultimate Guide to Preventing Weld Undercut: Tips and Techniques

Blog Article

Understanding the Art of Welding: How to Avoid Undercut Welding Issues for Flawless Fabrication Outcomes

Performance and accuracy are vital worldwide of welding, where even the least flaw can endanger the architectural integrity of a made piece. One typical obstacle that welders face is undercutting, a problem that can lead and weaken a weld joint to expensive rework. By recognizing the origin causes of undercut welding and carrying out effective strategies to avoid it, welders can elevate their craft to new levels of quality (Preventing weld undercut). In the search of remarkable construction results, grasping the art of welding to stay clear of undercut problems is not just a skill however a requirement for those pursuing perfection in their job.

Recognizing Undercut Welding

To stop undercut welding, welders must ensure appropriate welding criteria, such as changing the present, voltage, traveling rate, and maintaining the appropriate electrode angle. In addition, utilizing the appropriate welding technique for the details joint setup is vital. Using weaving motions or backstepping techniques can assist make certain proper weld metal deposition and minimize the probability of undercut development. Normal examination of welds throughout and after the welding procedure is also vital to catch any kind of undercut very early and make needed modifications to avoid more issues. Preventing weld undercut. By understanding the root causes of undercut welding and applying preventive actions, welders can attain high-grade, structurally sound welds.

Root Causes Of Undercut in Welding

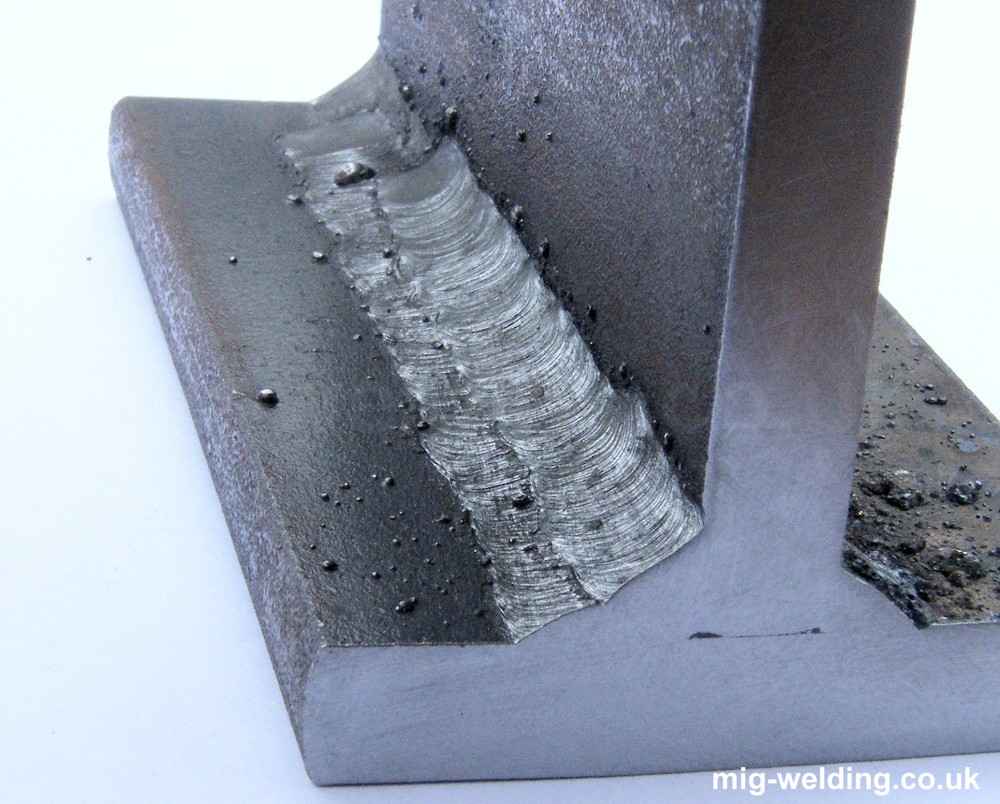

Understanding the aspects that add to damage in welding is crucial for welders to generate top quality, structurally audio welds. Damaging occurs when the weld metal does not correctly fill up the groove created between the base steel and the formerly transferred weld steel. Numerous elements can cause damage in welding. One typical reason is too much heat input. Welding at high temperature levels for extensive durations can cause the base metal thawing greater than wanted, resulting in undercut. Poor welding current or inaccurate welding rate can also add to undercut. Inadequate current might not supply adequate warmth to thaw the base and filler steels properly, while excessive speed can prevent correct blend, triggering undercut. Additionally, improper electrode angles or incorrect torch adjustment strategies can produce areas of low weld metal deposition, promoting undercut. Recognizing these reasons and implementing proper welding methods can help stop damaging issues, guaranteeing solid and resilient welds.

Methods to Prevent Undercutting

To mitigate the risk of undercutting in welding, welders can utilize strategic welding techniques intended at improving the quality and integrity of the weld joints. One efficient approach is to readjust the welding specifications, such as voltage, current, and take a trip rate, to make certain proper warm input and deposition. Maintaining an ideal electrode angle and guaranteeing constant travel speed can additionally assist stop undercut. In addition, utilizing the appropriate welding strategy for the specific joint configuration, such as weave or stringer grains, can contribute to minimizing undercutting. Preventing weld undercut.

Employing back-step welding strategies and controlling the weld grain account can additionally help distribute warmth equally and minimize the danger of undercut. see here now Routine assessment of the weld joint throughout and after welding, as well as carrying out high quality guarantee actions, can aid in resolving and spotting undercutting problems immediately.

Relevance of Correct Welding Specifications

Choosing and maintaining suitable welding parameters is crucial for achieving successful welds with marginal flaws. Welding specifications refer to variables such as voltage, existing, travel speed, electrode angle, and protecting gas circulation price that directly impact the welding procedure. These parameters must be thoroughly readjusted based upon the kind of material being welded, its density, and the welding technique employed.

Appropriate welding parameters make sure the ideal quantity of warm is applied to melt the base steels and filler material uniformly. If the criteria are set also high, it can lead to too much warmth input, triggering burn-through, distortion, or spatter. On the various other hand, if the criteria are also low, insufficient combination, lack of infiltration, or damaging may take place.

Top Quality Guarantee in Welding Operations

Conclusion

In final thought, grasping the art of welding requires an extensive understanding of undercut welding, its causes, and methods to avoid it. By guaranteeing hop over to here proper welding criteria and carrying out quality control practices, flawless construction results can be attained. It is crucial for welders to continually pursue quality in their welding procedures to stay clear of undercut problems and generate top notch welds.

Undercut welding, a common defect in welding procedures, takes place when the weld metal does not properly fill up the groove and leaves a groove or anxiety along the welded joint.To prevent undercut welding, welders need to guarantee appropriate welding parameters, such as adjusting the current, voltage, travel rate, Click This Link and maintaining the correct electrode angle. Inadequate welding wrong or current welding speed can additionally contribute to undercut.To reduce the threat of undercutting in welding, welders can use calculated welding techniques intended at boosting the quality and honesty of the weld joints.In verdict, mastering the art of welding calls for a comprehensive understanding of undercut welding, its causes, and techniques to prevent it.

Report this page